Previous posts in the New Narrows Bridge Series:

- The Two Towers I: Introduction

- The Two Towers II: History of the Narrows Bridges

- The Two Towers III: The Caissons

- The Two Towers IV: Anchor Management Class

- The Two Towers V: The Tour Begins

- The Two Towers VI: Struttin’ My Stuff

- The Two Towers VII: To the Top

- The Two Towers VIII: Stairway to Heaven

- The Two Towers IX: Spinning Beginning

The process of laying the wires begins by securing one end to the anchorage. This wire is then looped up and over the spinning wheel, and the top wire returns to the spool which feed it. As the spinning wheel moves outward from the anchorage along the tram, the lower wire–called the dead line — remains fixed, while the upper wire–the live line–is drawn out from the spools onshore, much like a fishing line after a strike.

As the wheel moves outward, it lays both lines in their selected position — guided by the positioning forks and the saddles on both towers — until the opposite anchorage is reached.

The complexity is greater than it sounds, however: the spinning wheel can carry up to four simultaneous loops — effectively laying down up to 8 wires in one pass. The process is automated but under manual control and supervision; when working at optimal efficiency, the spinning wheel can achieve speeds up to 40 miles an hour. Workers are positioned on the catwalks at intervals to monitor the process and address any problems or glitches which may arise.

Once the wheel reaches the oppositie anchor, the loop (or loops) of wire are removed from the spinning wheel and placed around the strand shoe (see the previous post), a semicircular casting with grooves for the wires, secured by anchor bolts to the opposite anchorage. When 454 wires have made this journey, they are bundled into a single strand or tendon. A total of 19 strands comprise the final cable, which is then compacted, wrapped, and sealed with epoxy to form the final cable.

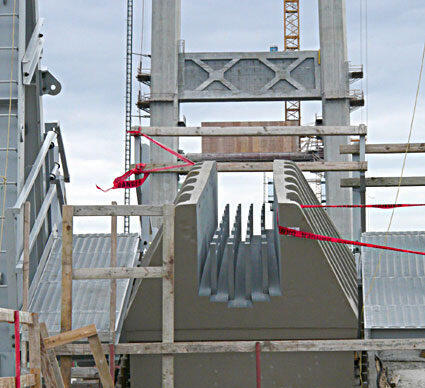

As the strands enter the anchorage, they are disbursed by a specialized saddle called a cable sorter. Splaying the individual tendons as they enter the anchor plate greatly increases the cross-sectional area and distributes the pull on the anchorage over a wider area.

Watching the cable spinning in action is fascinating — and has been the precipitant cause of more than a few fender-bender accidents on the existing bridge, as gawking rubber-neckers on their cell phones have a tendency to back-end their SUVs into the Mini Cooper they’re following — not pretty. It’s far more pleasurable — and safer — to watch from the walkway — although passing drivers are wont to wonder if you’re planning a deep-six dive from one of the favorite suicide spots in the South Sound. So I carry a camera and smile a lot to avoid such untoward suspicions.

Once the cable tendons are completed and secured to the anchors, they will be joined together into one massive unit and compacted, which we’ll cover next.